Network Rail – TP Sites

| Client: | Network Rail |

| Services | Earthing Study & Design |

| Sector: | Rail |

| Status: | Complete |

What was the problem?

Network Rail operates and maintains an extensive Rail network in the UK with many thousands of high voltage assets old and new, including substations and 3rd rail traction power (TP) sites.

Many of these substations and TP sites pre-date the more recent changes in standards concerning how a site is classified – hot or cold?

You can learn more about ‘hot sites’ from our 15-minute webinar here.

Part of every asset owner’s legal duty (not just Network Rail) is to identify and understand all those sites that might present a hazard both to its workers and innocent 3rd parties, such as the general public and their neighbours, during an electrical fault.

How did we solve it?

Armed with a list of multiple problem sites that fell outside the benign cold classification (ENA 36) – we took the risk off the table for Network Rail by carrying out the following preliminary field works.

Field Survey Works

- Soil resistivity measurements to determine the electrical properties of the local geology

- Topographical, laser scans and ground-penetrating radar surveys to map out the structures and buried services

- Review of geological records

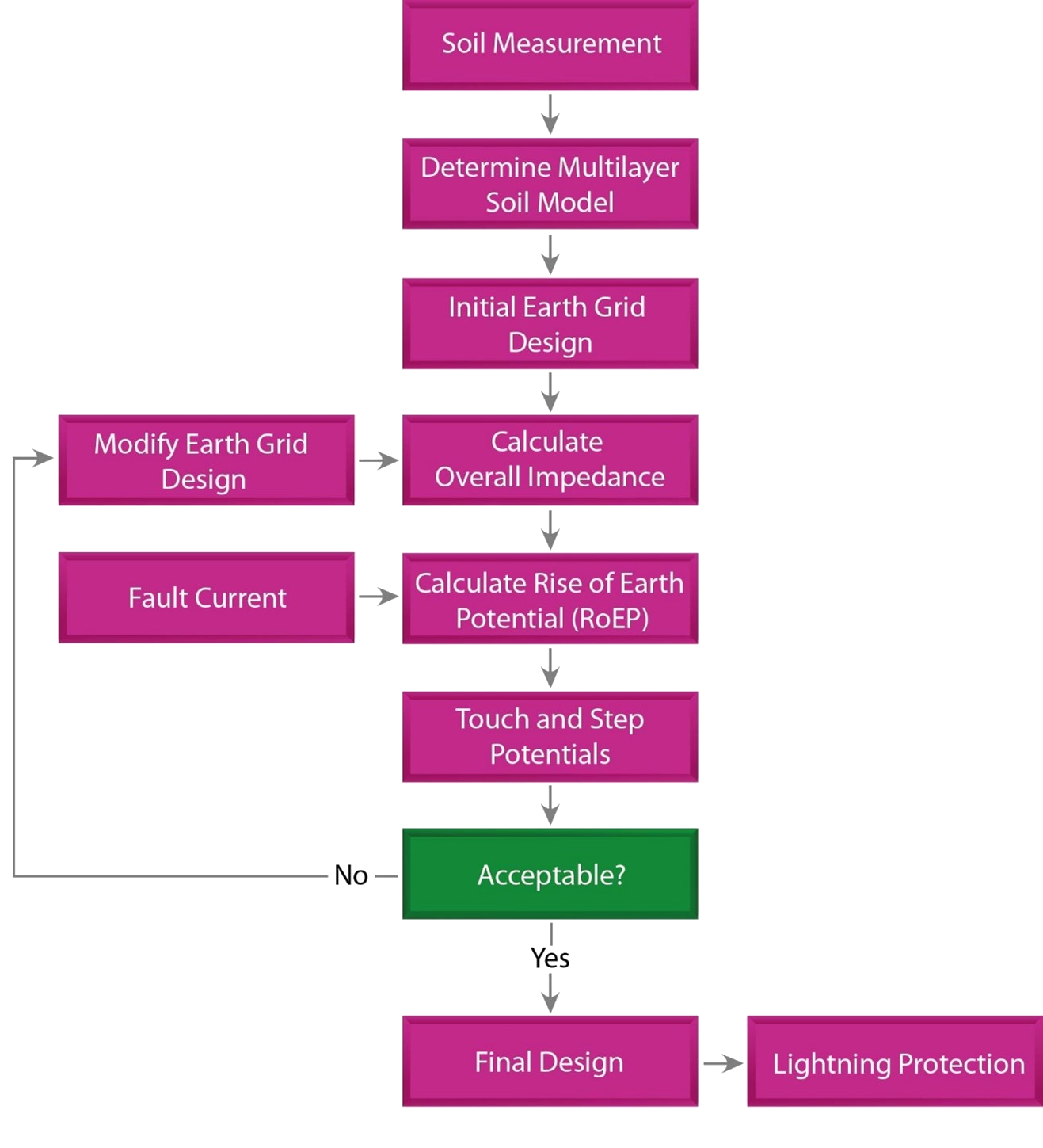

The fieldwork is aimed to inform the next step shown in the flowchart, which is the Earthing Study.

Earthing Study

The purpose of the Earthing Study to model each site’s electrical configuration and Rise of Earth Potential (RoEP) performance during a fault using top 1% electromagnetic software tools XGSLab.

It's at this point that the site's existing earthing arrangement can be 'stress-tested' in a virtual environment, and the current hazard can be verified together with exploring multiple scenarios and options to mitigate the sites that are a problem.

Using these advanced modelling techniques means the solution can be 'right-sized' ahead of any expensive construction to break ground, etc. And armed with good quality data from the fieldwork, top 1% software tools by some of the best minds in the business, gives confidence to the final design ready for construction de-risking the design process, controlling costs and optimising the amount of materials and resources being deployed.

Detailed Design

Knowing what solution will work best from the Earthing Study allowed for a relatively easy transition to a detailed design of the earthing solution producing easy-to-understand CAD-drawn layouts for the non-specialist civils construction team to work from. The process didn’t stop there.

Validation and Verification (V&V)

To close out the process, the final step is to revisit each site again to physically earth test and measure the newly install arrangements to check that the actual earthing performance matches with the designed predictions.

On completion of the V&V, records were handed over so that the client’s maintenance team has something meaningful to work from and to help the next generation of engineer if the standards are revised in the following years to come.